For additional information and details, please don’t hesitate

to contact our production team.

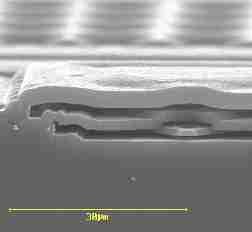

Surface micromachining is the fabrication of micromechanical structures by deposition and etching of thin structural and sacrificial films. Thus, simple microstructures like beams or membranes as well as complex structures like linkages or encapsulated resonators can be fabricated on top of a silicon substrate. A processing sequence using polysilicon as micro-structural material and silicon dioxide as sacrificial layer is significant part of this procedure.

The main features of the surface micro-machining technology are the small microstructure dimensions and the opportunity to integrate micromechanics and microelectronics on the same chip. By use of VLSI compatible batch processing, low cost microstructure fabrication can be achieved for high volume applications.